|

|

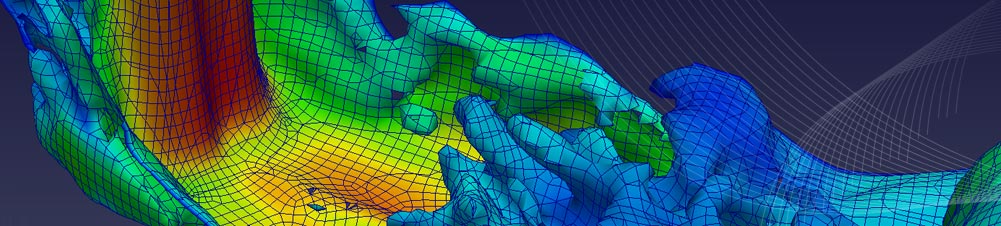

OPENFOAM Thermal Hydraulic two-phase flow

|

You wish to keep the control of the model and realize your own studies. INOPRO iao develops the model and validates it in comparison with your data or published data.

|

|

Development of OPENFOAM models and validation

|

Problem encountered

- Process knowledge.

- Process adaptation and sizing.

- Quantitative and forecasting simulation.

Objectives

- To establish a representative model for the bubbling process compatible with the project’s constraints.

- Validation through experimental comparisons.

Solutions

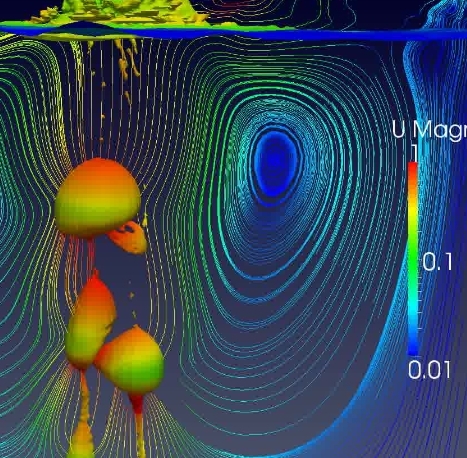

- Two-flow 3D simulation

- INOPRO iao suggests OPENFOAM use for computation time efficiency.

- Establishment of a bubble "breakdown" model

- Solver choice

- Mesh sensitivity

|

Simulation of two columns of bubbles |

|

Other tools or examples of development of models

|

For all the tools we use (COMSOL MULTIPHYSICS, FLUENT ...) the approach is similar : models choice , geometrical hypotheses, boundary conditions, meshing... According to the expected degree of precision we afford a specific approach of validation, sometimes making comparison with our client's measures. We do this systematically in the use of OPENFOAM, particularly through the choice of the appropriate solver.

This approach was recently used for a two-phase flow simulation in bubbling (brewing), spraying (paint), studies of surface (water tank, ship or others liquefied gas applications...).

|

|

Video Openfoam simulation

|

|

|

If you are interested in the topics discussed in this page, please contact us by e-mail or through our contact form |