Context

As part of a project of a new material development and its manufacturing process by crystal growth, the client seeks to know and understand the thermal behaviour of this liquid material and its impact on the functioning of the equipment. Measurement inside the process is impossible, so simulation and the reduction of uncertainties approach save time in the industrialization process.

Objective

To provide a thermal characterization of the liquid material and of all the equipment.

Process

- Simulations of heat transfers by conduction, by liquid and gaseous convection and by radiation within the equipment.

- Systematic study of sensitivity to uncertain parameters (emissivity),

- Correlation between the simulations results and the available temperatures measurement (regulation),

- Validation of the approach comparing measuresand transitory simulations results.

Results

- Degre accuracy

- Characterization of thermal gradients before solidification

|

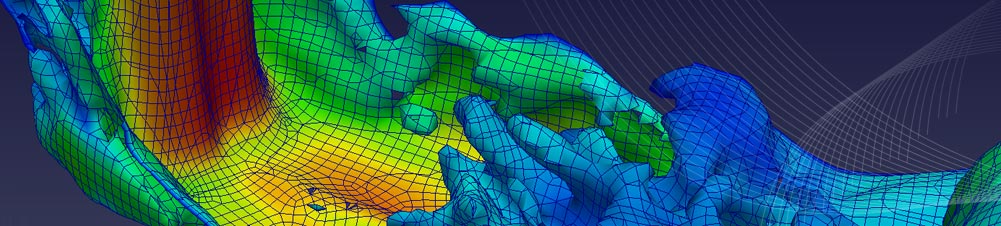

Desirability example according to two studied parameters.

The red zone corresponds to a good correlation ( desirability=1), the blue one to a lack of correlation. The area of good correlation, at the bottom of the diagram, corresponds to non-physical solutions

The desirability translates the good consistency between simulated temperatures and measures.

Results of the sensitivity study to several parameters were unintuitive, so the approach efficiency lies on systematic recourse to a design of digital experiments

|