Drying a wood chip pile

Problem encountered

The objective of the drying test performed on a chip bin was to understand the drying mechanism, to validate the importance of the process and to quantify its impact on a large industrial plant. Nonetheless, mere measurings do not provide sufficient data for theoretical understanding. Extrapolation is not possible without understanding the mechanisms, and without models validation it would lack precision.

Objectives

- To provide the data required to explain the drying mechanism of a wood chip pile,

- To reproduce the measured drying time,

- To forecast the drying time, the average rate and the drying distribution according to the thickness of the pile and to the air-flow blowing conditions,

- To provide quantitative data for the technical and economic study included in the project.

Solutions

- Using a wood chip drying model from the recent literature,

- Introducing this specific model into a 3D model of air, vapour and heat flows into the chip bin,

- Using a simplified model to study the impact of thickness, temperature and air-flow blowing rate on the result.

|

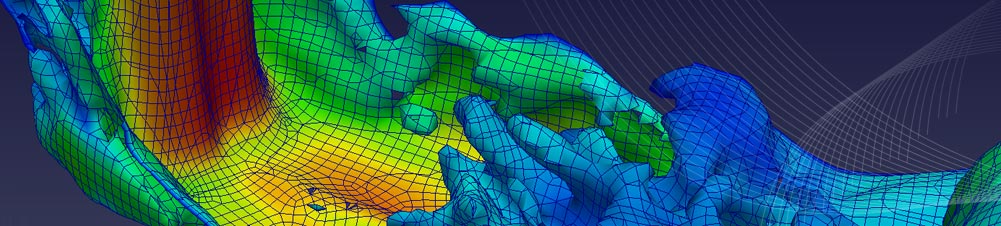

Drying front within the tested container. Air is injected at the bottom. The blue area corresponds to a humidity level below 15%, and the red area to a humidity level close to the initial value of 35%

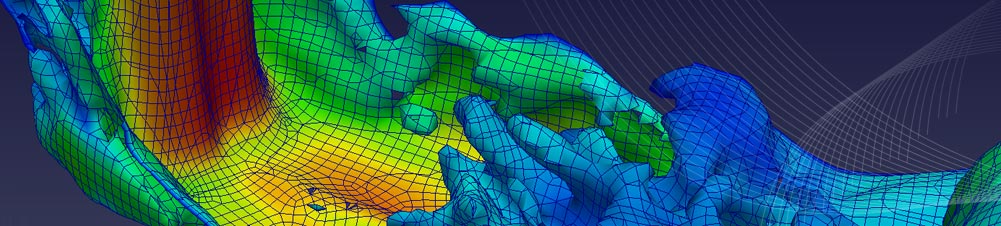

Humidity curve according to the height within the pile, for different blowing times |