Probleme encountered

During a waste treatment plant design, the project manager must ensure of no smells leakage.

Objectives

- To characterize the way chosen ventilation system works

- To validate the lack of smells dispersion outwards

Method

- 3D thermal airflow simulations for a range of scenarios

- Identification of thermal and smell sources

- Representation of different openings

- Sensitivity to wind scenarios

Solution

The study enabled to :

- Validate ventilation choices and sizing,

- Identify critical points,

- Suggest changes/adaptations.

Study carried out for

|

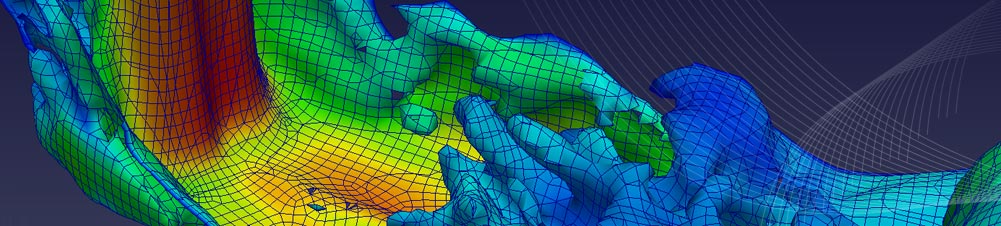

Normalized concentration, logarithmic scale. Wind effect on outdoor diffusion despite an air curtain

Speed under an air curtain

Ammonia concentration inside the workshop |