Context

For all monocrystalline material manufacturing by crystal growth processes, predicting the shape of the solidification front and the speed of crystallization, depending on the process conditions, is crucial for the quality of the final result, for the switch to industrial production and for productivity gains…

The specificities of pure materials prevent the use of the solidification models available in commercial simulation codes designed for metallurgy.

Process

- Development of a solidification front monitoring model

- Mesh deformation method, taking account of latent heat.

- Coupling with thermal transfers through a pseudo kinetic model

- Adaptation of the model to each material

- Simulation with or without accounting for liquid and gaseous convection

Results

- Knowledge of the shape and speed of solidification

- Assistance for process conditions adaptation.

|

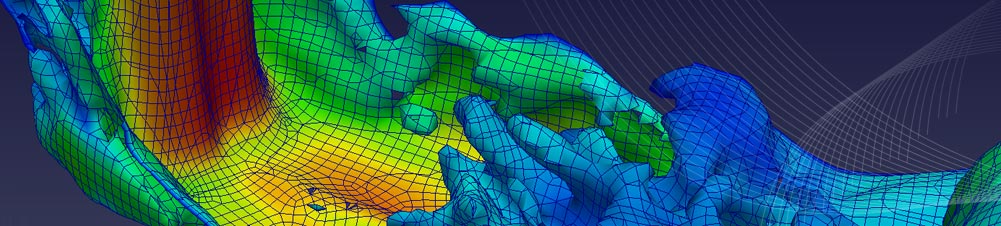

Monitoring of solidification front, checking for coherence with the isovalue of the fusion temperature

Speed of convection cell before solidification. The instability of this type of structure is one of the crucial issues of simulation and of the process |